Explore the impact of pH on beverage production, from microbial safety to flavor, color, and texture. Let’s find the best processing technology for optimal results in this article.

Contents

ToggleIntroduction

The selection of appropriate processing technology is crucial in beverage manufacturing, with pH being one of the most critical factors influencing this decision. pH level not only affects product stability and safety but also determines the type of processing equipment and parameters required for optimal production. This article explores the relationship between pH and processing methods and guides manufacturers in making informed decisions to optimize their beverage production.

pH levels in beverages

pH is an essential parameter in the production of beverages, as it indicates the amount of hydrogen ions present in a liquid, ranging from 0 to 14. It measures how acidic or alkaline a liquid solution is. This pH level affects multiple aspects of beverage production, including microbial stability, chemical stability, and equipment requirements. There are typical pH ranges for beverages:

- Highly acidic beverages (pH < 4.6): Fruit juices, carbonated drinks, energy drinks, flavored teas.

- Neutral to slightly acidic beverages (pH 4.6 – 7): Brewed teas, milk-based, and plant-based beverages.

- Alkaline beverages (pH > 7): Functional drinks, enhanced waters, and some plant-based products.

In the beverage industry, pH is a major concern because it directly affects microbial growth. Microorganisms like bacteria and molds thrive in specific pH environments. Beverages with a pH below 4.6 are considered acidic enough to inhibit the growth of harmful pathogens such as Clostridium botulinum, making them inherently safer. On the other hand, beverages with a pH above 4.6 require more stringent sterilization and filling processes to ensure safety and shelf stability.

The pH also partly represents the color, flavor, and texture of the beverage. Acidic drinks have brighter, more aromatic flavors and are more stable, while higher pH beverages, such as dairy, can easily lose flavor, change texture and significantly reduce product quality. Consequently, it is essential for manufacturers to carefully select the appropriate processing techniques and heat treatments to preserve the flavor and quality of the final product.

Overview of beverage processing technologies

Various processing technologies are researched and developed to cater to specific beverage types, ensure microbial safety, and maintain product integrity. These technologies are designed to sterilize the product, the packaging, or both, depending on the beverage’s specific requirements. Hot Fill, Aseptic, and Retort Processing are common processing methods that are widely used in the beverage industry.

Hot-fill processing

The process begins with the beverage being heated to the required temperature, typically 85°C and 95°C in a heat exchanger or cooking vessel. The hot product is then maintained at this temperature throughout the filling process. After being filled into containers, they are sealed and inverted or laid horizontally to sterilize the closure. These containers are typically held for about 30 seconds to ensure adequate sterilization of the package surfaces. This method is cost-effective and widely used for beverages. However, its high heat can degrade heat-sensitive ingredients, making it unsuitable for products requiring delicate flavor or nutrient preservation.

Aseptic processing

Aseptic processing is a more advanced technology where the product and packaging materials are separately sterilized and brought together under sterile conditions. This process involves ultra-high temperature (UHT) treatment of the product, typically at temperatures above 135°C (275°F) for a few seconds, followed by rapid cooling before filling. Simultaneously, the packaging is sterilized using methods like hydrogen peroxide vapor. The sterile product is then filled into the sterile packaging in a controlled, sterile environment. With aseptic, the quick heat treatment minimizes thermal degradation, maintaining the beverage’s natural flavor, aroma, and nutritional content.

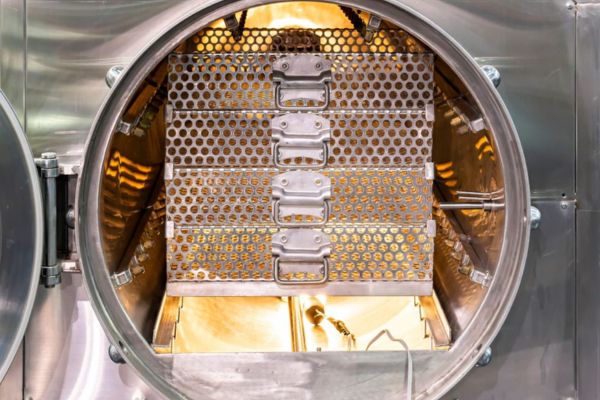

Retort processing

Retort processing sterilizes the beverage and its packaging simultaneously. After the product is filled and sealed, the entire package is subjected to high temperatures (typically 115-121°C) in a pressurized chamber for a specified period (about 30 minutes). This ensures the elimination of both pathogenic and spoilage microorganisms. However, prolonged exposure to high temperatures can alter the taste, texture, and nutritional content of sensitive ingredients.

Choose beverage processing technologies based on pH levels

The relationship between pH and microbial growth makes it essential to select processing technology based on the acidity or alkalinity of the beverage. The appropriate processing method can ensure optimal sterilization efficiency, minimizes the risk of harmful microorganism growth, and safeguards consumer health.

Acidic beverages (pH < 4.6)

Acidic beverages include fruit juices, carbonated drinks, energy drinks, and certain types of flavored teas. These products naturally inhibit the growth of harmful bacteria due to their low pH, so the selection of processing methods is relatively simple. Most methods can be applied to this product group. However, to optimize costs and retain the natural flavor of the drink, hot fill and aseptic processing are the two preferred methods.

- Hot fill processing is often the technology of choice for acidic beverages due to its simplicity and cost-effectiveness. The combination of heat treatment and low pH effectively prevents the growth of pathogenic bacteria and most spoilage organisms. Nevertheless, this processing method is not recommended for beverages with heat-sensitive ingredients, as long exposure to high temperatures can change its flavor and nutritional value. Besides, hot fill processing requires packaging material that must withstand heat.

- Aseptic filling achieves outstanding efficiency in both killing microorganisms and pathogenic bacteria as well as maintaining the inherent flavor of the beverage. However, due to its high cost, it is often applied for premium beverages with delicate flavors or nutrients, such as cold brew teas or vitamin-enriched drinks.

Neutral to slightly acidic beverages (pH 4.6 – 7)

Beverages in the medium pH range, including brewed teas, milk-based drinks, and plant-based beverages like almond or oat milk, require more careful consideration in processing technology selection. These products do not have the natural antimicrobial protection of high-acid beverages but may not necessarily require the most intense thermal treatment.

Aseptic filling is a common advanced technology for these products because it minimizes quality impact through rapid heating and cooling and is highly effective for beverages with sensitive ingredients. This method extends the product’s shelf life without using any preservatives. Moreover, the aseptic processing is also flexible in packaging options, suitable with several packaging materials such as paper, PET, etc.

Alkaline beverages (pH > 7)

Some alkaline beverages that can be mentioned are functional drinks, enhanced waters, and certain plant-based products. These beverages often contain added minerals or nutrients to achieve their pH. Alkaline beverages pose the greatest challenge in processing requirements due to their high pH environment, which can support microbial growth. Therefore, processing conditions need to be most stringent to ensure safety and shelf-life stability.

Retort processing can handle the high microbial risks associated with alkaline beverages. Harmful bacteria will be effectively eliminated when the product is heated to high temperatures and kept for a long time. This method is especially suitable for beverages that require robust sterilization and packaging, such as protein shakes, functional drinks, or products containing particles. However, retort processing also has a large impact on product flavor, so it should be used for products with little change by heat.

To reduce the impact on flavor, Aseptic processing serves as an alternative technology for alkaline beverages. However, the extended maintenance time required at high temperatures poses a challenge, as it increases operational costs. This makes the application of this method less popular for these products.

Conclusion

The pH of a beverage is a fundamental factor in determining the appropriate processing technology. Acidic beverages with a pH below 4.6 are well-suited for hot fill or aseptic filling, offering a balance of cost-effectiveness and quality preservation. For neutral to slightly acidic beverages, aseptic filling with UHT treatment can ensure sterility without compromising delicate ingredients. Alkaline beverages benefit most from retort processing, which provides the robust sterilization needed for long shelf life. By understanding the interaction between pH and filling technology, manufacturers can optimize their processes to produce safe, high-quality beverages.

About Future Generation Co., Ltd

Future Generation Company Limited is one of the largest beverage suppliers in Vietnam, with 26 years of experience in production and export. FGC is equipped with modern machines such as Hotfill PET and TetraPak, ensuring high-capacity production. FGC strives to achieve our mission to become Vietnam’s leading healthy beverage company. Our factories also meet international standards such as ISO, HACCP, etc. In addition, we constantly innovate our machinery system, strengthen production capacity, and increase productivity.

FGC also provides Private Label Services. With this service, we can help customers research and formulate beverages, design product label packaging, and create their own brands. This is an ideal solution for small and medium enterprises. Moreover, FGC provides free samples for customers to test before bulk orders. We also ensure delivery as fast as possible.

Contact

Address: R4 building, Office Quarter 02, Royal City, 72A Nguyen Trai St., Thanh Xuan Dist., Hanoi.

Phone: +84 24 73 000 125/ +84 24 73 063 369

Mail: info@vietnam-tea.com

Website: https://oem-fgc.com/

Facebook: https://www.facebook.com/fgcvietnamtea

LinkedIn: https://www.linkedin.com/company/fgcvietnamtea/

Alibaba.com: https://fgcvietnam.trustpass.alibaba.com/