If you are new to can packaging, you may wonder which type to choose between 2-piece and 3-piece cans for your beverages. Follow this article to find the answer.

Contents

ToggleIntroduction

Choosing suitable packaging is one crucial step in launching a new product. 2-piece and 3-piece cans are among the most popular types of metal cans used in the food and beverage industry. Two types with different structures, manufacturing processes, advantages, and disadvantages, will suit different products. Let’s explore them in this article.

Understanding 2-piece cans

What is a 2-piece can?

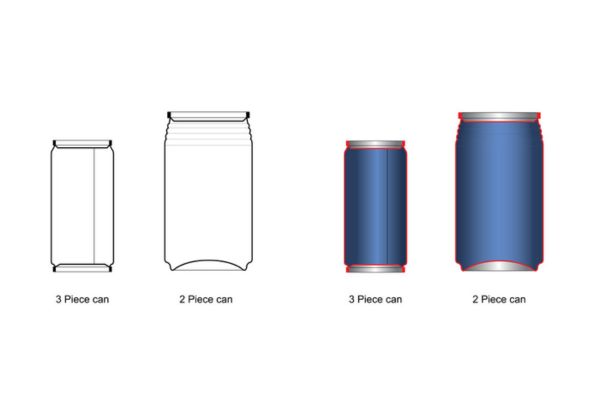

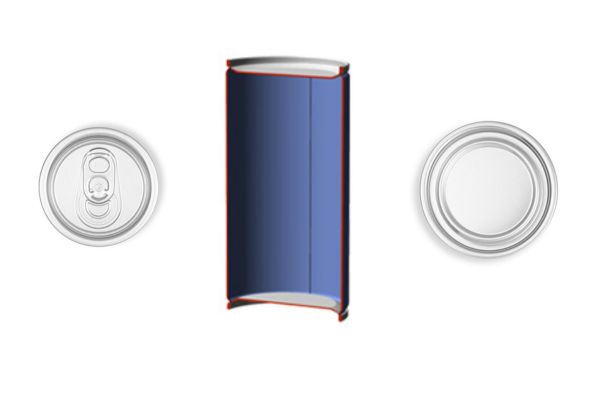

A 2-piece can is a metal container often made from aluminum or steel. It includes two components: the body and the lid. The body is linked with the bottom end, made with a single piece of metal forming cylindrically. Meanwhile, the lid, or the top end, is a separate piece of metal attached to seal the top. They are widely applied in the beverage industry for carbonated drinks, tea, coffee, etc.

How is a 2-piece can manufactured?

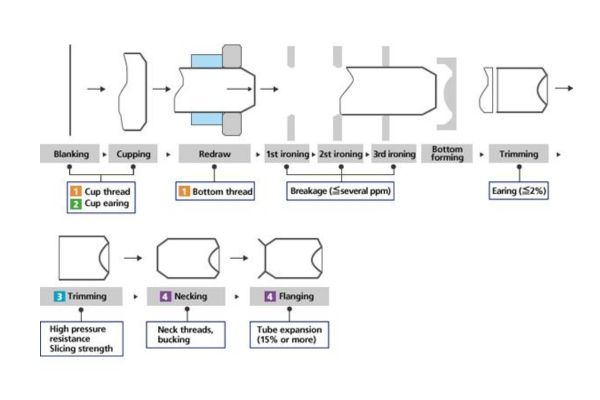

2-piece cans are often made by stretching a metal sheet to create a smooth body. Advanced methods are applied to ensure strength, durability, and seamless structure. The two common methods involved are draw and iron (D&I) and draw and redraw (D&D). In the D&D method, the can is redrawn multiple times to get uniform height and thinness.

- Large aluminum coils are unrolled, lubricated, and cut into circular blanks to fit the cans’ dimensions.

- Each blank is fed into a press and drawn into a cup-like shape using high pressure.

- The cup is pushed through ironing dies, and the cup’s wall is stretched to the desired height.

- The can body is trimmed and all the rough edges are removed.

- The cans are washed to remove the lubricants and metal particles.

- After the cans are dried, an inside protective coating is placed to stop corrosion and protect the beverage quality.

- The top part of the can is constricted to make room for the lid. For later lid seaming, a flange is made around the rim.

- Each can is checked to ensure the quality and transported to the beverage manufacturing plants.

- After the cans are filled, the lid is added and sealed using a high-speed seaming technique.

What are the advantages of 2-piece cans?

One of the outstanding features of 2-piece cans is the elimination of side seams. It can help improve strengths and reduce the risk of leaks and contamination, which is crucial in beverage packaging. 2-piece cans also have better resistance to internal pressure and external impact, making them ideal for various beverages, typically carbonated drinks. The stretching process turns the metal into lightweight 2-piece cans, which are easier and cheaper to transport and handle. Their seamless surface also allows smooth printing of labels and designs.

What are the disadvantages of 2-piece cans?

The production of 2-piece cans might be more efficient with fewer raw materials; however, it is usually more complex and requires specialized equipment and technologies. Besides, it is quite limited in materials and shape customization because of the deep-drawing or D&I manufacturing process.

Understanding 3-piece cans

What is a 3-piece can?

As the name suggests, a 3-piece can is a container with 3 separate components, including a body, a lid, and a bottom. The can body is made by rolling a rectangular metal sheet into a cylindrical shape and sealing or welding together. Meanwhile, the can lid, also called the top end, is a separate piece of metal that seals the top. The bottom end is another component that creates the can base. These cans are typically made of tinplate steel and are widely used for food and some beverages.

How is a 3-piece can manufactured?

The process of producing 3-piece cans is slightly different from 2-piece ones.

- First, the metal sheet is cut into rectangular pieces and rolled into a cylindrical shape. Then, it is joined together by welding, soldering, or seaming.

- The seam is often covered with a thin layer of protective lacquer to avoid corrosion.

- Flanges are formed by curving the can body’s top and bottom edges outward.

- The bottom end is placed and seamed. The seam is tightly pressed and rolled to form an airtight and leak-proof seal.

- Qualified cans are transported to beverage factories. They are filled, added to the top lid, and sealed carefully.

What are the advantages of 3-piece cans?

The can body, bottom, and lid are blanked, molded, and sealed to make a 3-piece can. Therefore, it might be easier to modify shape and size depending on the brand’s purposes. This type of can is also adaptable to a variety of raw materials. In addition, 3-piece cans have good rigidity.

What are the disadvantages of 3-piece cans?

Because 3-piece cans require side and top seams, they have more potential weak points. Side seams could weaken the cans’ structure and increase their vulnerability to contamination or leaks. Therefore, it is not suitable for high-pressure beverages, such as sodas, beers, or other carbonated drinks.

Choosing between 2-piece and 3-piece cans for your beverages

Many manufacturers, especially those new to the beverage industry, may wonder which packaging is ideal for their products: 2-piece or 3-piece cans. The beverage sector is dominated by 2-piece cans because of their superior sealing qualities, lightweight features, and cost-efficiency.

Manufacturing efficiency

Compared to 3-piece cans, which have separate bottom, body, and top, 2-piece cans are made up of two parts: a body and an end. This structure can help reduce the manufacturing time. Although the setup might be costly, it is more suitable and efficient for mass production.

Cost savings

2-piece cans require less material because they do not have a bottom or side seam, which helps lower the total cost. Besides, the shipping cost is reduced thanks to their lightweight characteristics.

Better sealing

The seamless body of 2-piece cans allows them to resist higher pressure and lower the risk of leaks. Therefore, it is perfect for carbonated drinks such as sodas, beers, and soft drinks. A tighter seal can lengthen the life of products inside and keep them fresh for longer by decreasing the oxidation and contamination process. Higher durability can also reduce breakage during shipping.

Enhanced consumer experience

Without bottom and side seams, 2-piece cans provide a smoother surface, bringing a better experience for consumers. Additionally, the seamless body enables excellent printing and decoration.

However, 3-piece cans may also be applied in the beverage industry, mostly for drinks that do not require high-pressure resistance. They are more popular in food packaging, such as canned vegetables, soups, etc., because they are more flexible in shapes and sizes. They also can be used in areas where facilities for 2-piece cans are not available.

Explore other types of beverages:

PET bottles, CAN, paper cartons: Which beverage packaging is the best?

Conclusion

The choice between 2-piece and 3-piece cans depends on your product types, production scale, and budget. However, if you are planning to launch beverage products, 2-piece cans will be the optimal choice, thanks to their manufacturing efficiency, cost savings, better sealing, and customer experience.

About Future Generation Co.,Ltd

Future Generation Company Limited is one of the largest beverage suppliers in Vietnam, with 30 years of experience in production and export. FGC is equipped with modern machines such as Hotfill PET and TetraPak, ensuring high-capacity production. FGC strives to achieve our mission to become Vietnam’s leading healthy beverage company. Our factories also meet international standards such as ISO, HACCP, etc. In addition, we constantly innovate our machinery system, strengthen production capacity, and increase productivity.

FGC also provides Private Label Services. With this service, we can help customers in researching and formulating beverages, designing product label packaging, and creating their own brands. This is an ideal solution for small and medium enterprises. Moreover, FGC provides free samples for customers to test before bulk orders. We also ensure delivery as fast as possible.

Contact

Address: R4 building, Office Quarter 02, Royal City, 72A Nguyen Trai St., Thanh Xuan Dist., Hanoi.

Phone: +84 24 73 000 125/ +84 24 73 063 369

Mail: info@vietnam-tea.com

Website: https://oem-fgc.com/

Facebook: https://www.facebook.com/fgcvietnamtea